Preventing contamination is a common priority for Food and Beverage processors. As these facilities grow and increase in efficiency, a single production run impacted by contamination can lead to a product recall and impact the health of tens of thousands of consumers. Until recently, metal detectors and X-rays played the dominant role, but increasingly the trend favors machine vision systems which have proven more effective at identifying small plastics and rubber contaminants. Continued implementation of machine vision for Extraneous Materials detection will help reduce food waste as well as lower costs and the risk of recalls.

Food and beverage production facilities often perform routine wash down of production equipment with high-pressure washing equipment using caustic detergents and chemicals and high temperatures to make sure contaminants are eradicated. Producers must have IP69K-rated enclosures, which promise the highest level of protection based on the Ingress Protecting (IP) rating system, to keep the delicate inspection systems safe and in consistent working order.

IP69K Highest Level of Protection Available

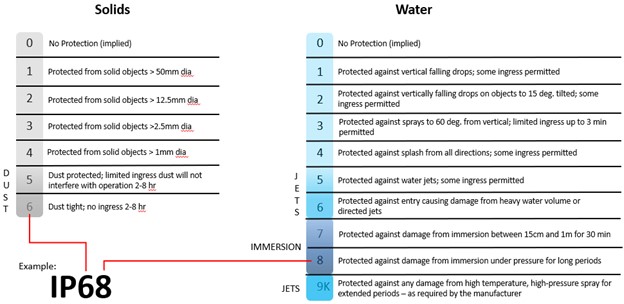

“IP Code classifications and ratings have been defined by IEC standard 60529 (European equivalent EN 60529) for routine use across all applicable industries and disciplines and are neither restricted to nor necessarily defined for machine vision use exclusively. IP code designations comprise two aspects: solid and liquid (typically defined as water) intrusion potential denoted by IPxy, where “x” represents the solid and “y” represents the liquid intrusion levels. The original standard defined 6 solid (1-6) and 8 liquid (1-8) levels, with each progressively higher number up the scale representing more complete protection compared with those levels listed below it (Fig.47). A zero (0) entry suggests no protection as defined for the other levels, and a recent addition to the definition includes IP69K, which is defined as complete IP protection under high temperature and high-pressure (K) water jet spray.”

“We can further define each “x” (solids) scale value by particulate size blocking level, with IP5y and IP6y specific to dust size protection. Similarly, the “y” scale levels are defined by the volume and velocity of impacting liquids, with the IPx7 and IPx8 levels specific to depth and time of immersion in water.”

Fig. 47: Ingress Protection (IP) Ratings Table based on IEC 60529 and later additions.

“Historically, standard IP rating practice among machine vision component manufacturers has been to self-assign values based on interpretation of the above-defined levels, but more recently, some manufacturers have enabled the services of accredited, independent testing laboratories, and hence those tested and passed products may be assigned “IPxy Certified,” rather than the subjective “IPxy Rated” assignment and label. For some customers, formal certification is a necessity.” (Martin, 2022)

In addition to enhanced ingress protection for food, beverage, and some biomedical applications – consider enclosures with smooth, crevice-free surfaces, and/or materials with chemical inertness. These characteristics prevent food or other particulates from collecting on vision components and subsequently dropping into the food processing stream – and promote efficient cleaning practices.

Durable. Waterproof. IP Certified – Impenetrable Protection.

Advanced illumination UltraSeal IP69K Certified Washdown LED Lights are completely sealed, smooth, and durable enough to handle the most intense applications. The UltraSeal waterproof housing and unique engineering enable users to wash the lights completely free of food, dust, dirt, and other debris – without getting any materials caught in crevices or bolts on the face of the light.

UltraSeal is an entire series, with various types of lighting for different applications. There are options built to withstand demanding Food and Beverage production. The UltraSeal lights are available with a proprietary FDA-compliant finish, enabling them to withstand the rigorous cleaning requirements necessary to keep hygienic standards within food and beverage production facilities.

UltraSeal Washdown Lights have compelling rugged use applications in the field now, as well as use in clean rooms and controlled environments applications. The Ai IP69K certified lights are specifically engineered to withstand everything your application endures – from prolonged liquid immersion to high-pressure steam cleaning and even corrosive washdown solutions.

The UltraSeal Washdown Lights are manufactured with a proprietary nickel finish, providing superior corrosion protection. They are also engineered with an aluminum housing, making them 11x more thermally conductive than stainless steel – keeping your machine vision inspection application running cooler longer

IP69K rated crevice-free, corrosion-resistant vision lighting: Left – Back Lighting; Others – Front lighting.

To learn more about the IP69K Certified washdown lights view our View Product Video here.

Please consider signing up to receive industry news, our newest products, and application notes delivered straight to your email – click here to subscribe.

*Keep watching for our newly revised edition of Ai’s A Practical Guide to Machine Vision Lighting. Originally released in 2013, and shared countless times over, this in-depth analysis is considered within the machine vision industry as the variable “toolbox” of lighting types, techniques, tips, and tricks meant to help readers better direct their time, effort, and resources when embarking on a machine vision project. This new version is nearly 3x in size & scope, including new MLV topics, an introduction to new terminology, updates to applications, and dozens of new charts and illustrations.

Additional findings:

Annual reports provide figures for the detection of Extraneous Materials– US Department of Agriculture (USDA) reported that 984,554 pounds of animal products were recalled due to reports of Extraneous Materials in 2021. View summary detail here – https://www.fsis.usda.gov/es/node/4757

This represented approx. 6% of the overall total “Recalls by Reason” classification last year. This figure is down significantly when compared to 2019 findings where Extraneous Materials represented over 75% of the total “Recalls by Reason”. The pace of adoption for machine vision systems has increased significantly, rapidly replacing less capable, older technology metal detection and X-Ray inspection solutions.

Resources –

Martin, D. (2022, July). A Practical Guide to Machine Vision Learning [presentation material, unpublished]. Advanced illumination, Ann Arbor, Michigan.