When specifying LED lighting for machine vision applications, the LED wavelength can have a significant impact on the success of the vision inspection. When utilizing white LEDs, it’s important to understand that the radiated emissions are a combination of most of the wavelengths from the visible spectrum; for white LEDs, the color temperatures range from the warm, yellowish end of the spectrum to the cool bluish end and may ultimately impact the accuracy and robustness of your inspection. For this reason, it’s important to understand the concept of color temperature: how it’s measured, its impact on the success of your vision system, and how to ensure you source the best white LED light for your application.

Background on Color Temperature in LEDs

What is Color Temperature

Before diving into the more complex aspects of color variation, it’s important to begin with the basic understanding of color: the color of an object is generated from the wavelengths an object reflects or transmits, which is then perceived by the observer. It should be noted that color is not a physical or intrinsic property of an object. The human perception of the color can be dependent on many factors, including ambient light in a room, the texture of the object’s surface, object reflectivity, how the observer’s brain processes color (or does not, in the case of color blindness), and many other factors.

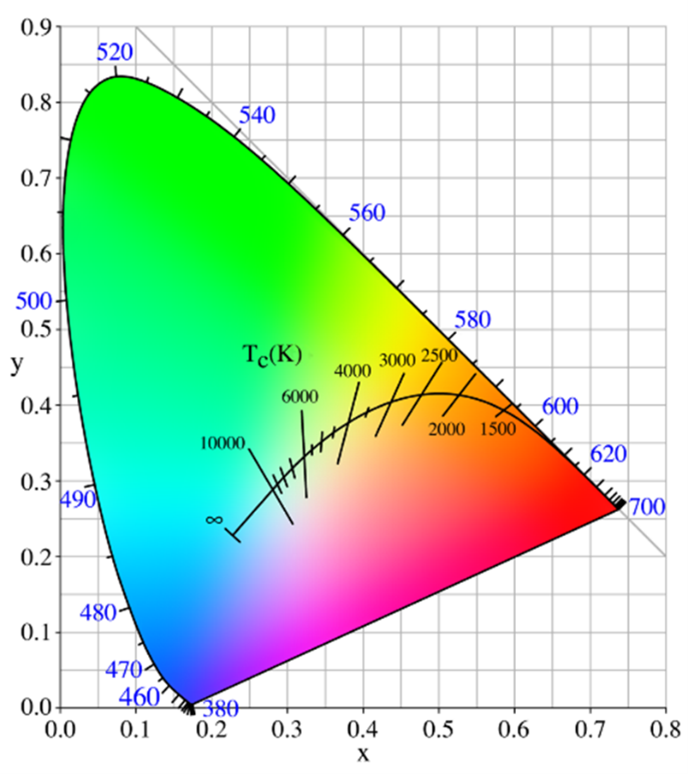

As a way to specify the exact color temperature of a light source, the Commission Internationale de l’Eclairage (CIE) developed a color model mapping system. This is illustrated by the Trimistus Ternary Chromaticity diagram, which plots the values of color using known X, Y, and Z coordinates (Figure 1).

Figure 1 – Trimistus Ternary Chromaticity Diagram.

This CIE color space is patterned after the three color receptors (red, green, blue) of the human eye and is the pinnacle gauge for color modeling. Using the coordinates from the diagram allows users to develop a color that is closest to what is perceived by human visual receptors, resulting in a more consistent way of analyzing and repeating colors – particularly beneficial in machine vision.

Characterizing Light: How We Measure Radiant Power and Light Color Temperature

There are multiple ways to characterize and specify light. One aspect is the power generated, expressed in either radiometric or photometric units, and another is color temperature (typically applied to white light).

Radiometric measurements are the physical measurements of optical radiation power over the entire electromagnetic spectrum. Radiant power may be conceptualized and specified as source power in Watts (W) or in geometric units measured away from the emitting source, often expressed as radiance (W/m^2/sr) or irradiance (W/m^2 at a specified distance). These measurements of light are typically gathered using a spectrophotometer.

Although the same source or geometric radiant power conceptualizations are applicable, photometric measurements are based on the human perception of light radiant power relative only to visible wavelengths. Photometric measurements are often expressed in lumens (lm) for a source or in geometric luminance (lm/m^2) or illuminance (lm/m^2/sr) at a distance from the source. As mentioned earlier, external factors can affect the performance of the human eye in perceiving visible wavelengths, which can reduce inspection accuracy and drives the demand for machine vision inspection.

The color temperature of light is expressed in Kelvins (K) and is modeled after black body radiators, which produce all light frequencies. The emitting body is called a “black body radiator” after the idealized color of the object (black) which makes the emission equations the simplest. Black body radiators emit a spectrum of wavelengths due to an increase in temperature as a result of agitated electrons; as a black body radiator heats up, the color it emits changes from red, through yellow, to white, and finally blue. This definition lends itself well to the standard incandescent tungsten light bulb filament that works similarly, since it emits a specific color temperature related to its resistive heating state.

The spectrum of colors also has a direct correlation with light wavelength, and Figure 1 demonstrates the result of combining light wavelengths to produce the same perception of color – again modeled after the three human vision receptors. Hence, some combination of these three primary colors – red, green, and blue – will produce white light, and this is the basis for color temperature as perceived by human vision and machine vision cameras.

Color Temperature: White

One important clarification in determining the color temperature of white LEDs is understanding the difference between Color Temperature and Correlated Color Temperature (CCT).

While color temperature is expressed based on black body radiators, LED and fluorescent lights do not emit light based on their thermal heating properties. As such, the concept of a Correlated Color Temperature was defined. CCT best expresses a color temperature based on human perception that most closely matches the illuminator light output; thus, if a broadband light source (i.e. white light) emits radiation close to the black body Planckian locus, it can be modelled and expressed by the CCT and results in the correct expression of LED white light. Additional information on color temperature and CCT can be found in Konica Minolta’s “The Language of Light”.

There are variations in the color temperature or CCT of white light, which explains the perceptions of “warm white”, “natural white”, “cool white”, etc. As the white light’s color temperature rises in Kelvins, there is more blue color, resulting in a “cool” white. When the color temperature is lower, there is more red light and is thus perceived as a “warm” white.

Measuring Color Temperature of White LEDs

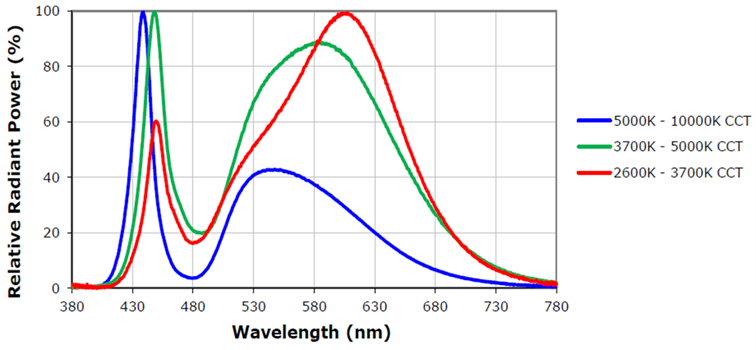

White LED lamps are typically powered by blue LEDs that appear white to the human eye through the use of a secondary emission from a phosphor that is deposited onto the LED diode. Early attempts at creating white LED light showed considerable blue content in the spectrum and effectively created the purplish, cold color temperature most often associated with surgical rooms. As phosphor chemistry evolved, a number of various LED color temperatures became available, each with a specific profile and relative height of the blue peak and red-orange “bulge” (Figure 2).

Figure 2 – Spectral profiles of white LED light of varying color temperatures, courtesy of Cree.

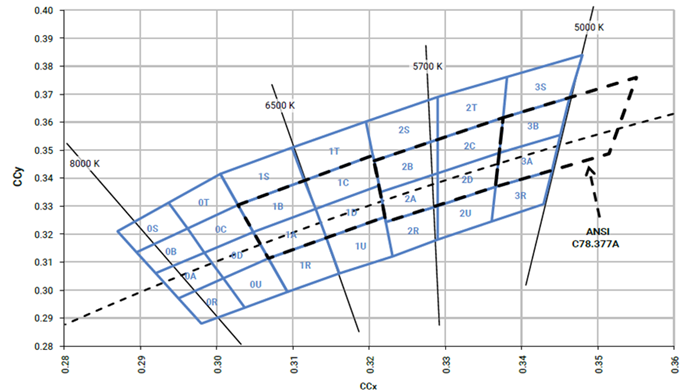

LED manufacturers sort their white LED’s into bins based on the specific range of color temperatures. The curved black line in Figure 1, known as the Planckian locus, describes the intersection of wavelengths upon which the color temperatures in the binning process are based. Figure 3 is a more detailed representation of the Planckian locus, demonstrating the white color temperature bins from 8000 K to 5000 K.

Figure 3 – Dashed line represents the Planckian locus derived from a black body perfect frequency generator, detailing typical white LED color temeprature bins, courtesy of Cree.

White LED Color Temperature in Machine Vision

As related to machine vision applications, the use of white LEDs, or alternatively a combination of monochrome colors, can deliver drastically different results, depending on the wavelength’s interaction with the inspected object’s physical properties. For a detailed article on the use of color in machine vision, view our application note here.

For white LEDs, the relative constituents of red, green and blue wavelengths can have a significant effect on an inspection result, depending on the vision application. Inspections requiring specific color representation for the purposes of accurate reproduction, identification, object matching/selection, or quality control of registered colors, are highly dependent on a vision operator’s understanding of two light parameters: white light LED light CCT and the Color-Rendering Index (CRI).

CRI is best described as how well object color is reproduced accurately in acquired images – or how realistic the image looks when compared to human perception. The higher the CRI, the better the light source’s capability is of generating an accurate color representation. Most white LED lights have a CRI ranging from 70 to 95, as compared to cool white fluorescent lamps with a CRI of 62.

Choosing the necessary color temperature of your white LEDs can mean the difference in a robust inspection that adequately separates similarly-shaded objects or applications inspecting more color-muted objects.

Color Temperature Example: Automotive Manufacturing Quality Control

A common Quality Control inspection process in the automotive industry is differentiating and matching interior plastic panels. In fact, it is common for many Tier 1 or Tier 2 automotive suppliers to produce precise grey color interior parts for multiple auto manufacturers, with each supplier receiving subtly different “shades” and hues of grey.

During the vision inspection, suppliers verify the grey scale of these panels to accurately match them with the corresponding auto manufacturer or model. Figure 4 illustrates a generic sample of hues in which the products are manufactured and represents an example of the challenges involved with accurately reproducing the grey scale for identification purposes.

Figure 4 – Grey scale for identification based on illumination CCT.

For example, it is evident how a specific color temperature may affect the image reproduction of flat grey (Figure 4 – center column under “Neutral”). This could skew the differentiation, identification, and matching between the subtly differing grey to brown panels in the automotive inspection application.

With a substantial amount of preparation and testing, it is possible to effectively calibrate a particular light’s CCT with a known part and create a relative reference and correction factor. However, this approach involves testing all known part variations and can be both difficult and time consuming, depending on the part source.

Additionally, for true color reproduction of non-grey objects and multiple color objects, specifying an individual CCT value may not be sufficient. In this instance, the Color Rendering Index (CRI) must also be introduced.

Specifying Color Temperature Ranges of White LEDs

A typical request that machine vision LED lighting manufacturers receive is whether it’s possible to specify a specific color temperature range or CRI value in an LED illuminator. There is both good news and not-so-good news: the good news is LED manufacturers now produce a wide selection of both CCT and CRI options but are unfortunately unable to provide a very narrow bin of CCT values.

This is a limitation imposed by the LED manufacturer due to their manufacturing processes. In any process of this type, there is a certain variation in both CCT and CRI values within the batch manufacturing runs. LED yields are tested and binned within certain ranges to optimize the salable yield. However, the manufacturer will often times opt to combine several adjacent sub-bins into one larger bin for sale. This results in the general inability to purchase sub-bins, and thus a narrower range of CCT values.

Reliable Color Temperature for Vision Inspection

At Advanced illumination, we perform quality control testing to verify the CRI and CCT values of the white LEDs we receive from our suppliers – resulting in an LED lighting product you can trust to perform as specified. If you’re not sure which color temperature is the most effective for your machine vision application, contact our team of lighting experts and they’ll work with you to find the most robust lighting solution for your application.