Abstract

LED lighting controllers play a pivotal role in ensuring optimal performance and imaging quality. As industries increasingly rely on machine vision for automation, inspection, and quality control, the selection of the right LED lighting controller becomes a critical determinant in achieving superior results.

Introduction

Engineered lighting plays a crucial role in ensuring reliable machine vision system performance. In addition to selecting the appropriate engineered lighting solution in terms of placement, path, illumination pattern, and wavelength, machine vision engineers must choose the right LED lighting controller to get the most out of their LED lighting solution.

This whitepaper will explore the nuanced differences between drivers and controllers, dissect the fundamental components of LED lighting controllers, and offer a clear and accessible understanding of their functionalities, limitations, and compatibility with diverse machine vision lighting solutions. It aims to help novices and experts alike navigate the complex landscape of LED lighting controllers for machine vision applications and make informed LED lighting controller decisions — whether they’re delving into the intricacies of machine vision for the first time or seeking to enhance existing systems or develop new ones.

By learning about the critical factors to consider when selecting the most suitable controller for specific machine vision setups, readers will be equipped with the knowledge and insights necessary for selecting and integrating an optimal LED lighting controller that will elevate the performance and efficiency of their machine vision systems.

The Importance Of Lighting In Machine Vision Applications

When it comes to machine vision systems good lighting is essential. While machines such as autonomous vehicles mostly rely on ambient light to operate, mostly rely on ambient light to operate, industrial machine vision systems usually incorporate engineered lighting and attempt to minimize the influence of ambient lighting. To achieve an effective, consistent, and robust image contrast between parts and their backgrounds, four methods are applied to enhance or even create feature-appropriate image contrast: geometry, structure, wavelength, and filters.

Geometry is the study of the spatial relationships between an object, light, and camera. Structure refers to the shape of the light projected onto the object. Wavelength refers to how the light is differentially reflected or absorbed by the object and its immediate background. Filters differentially block and pass specific wavelengths and/or light directions.

Vision system engineers have access to a wide range of light sources that cover a wide range of sizes, wavelengths, and illumination characteristics, complicating how to determine the best light source to achieve success with a given project.

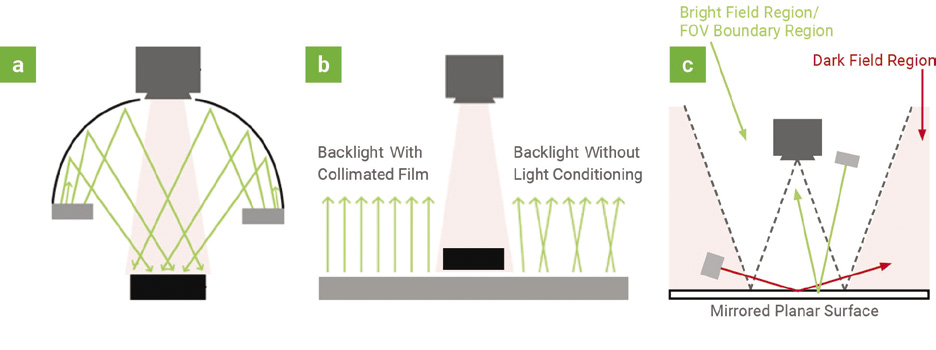

Figure 1a-c: Different lighting geometries; a – dome coaxial lighting, b- back lighting with and without collimated light conditioning, c – off axis front lighting with bright-field and dark-field sources

Engineered lighting can be differentiated in several ways. First, there’s front lighting and backlighting. A front-lit scene has the light source on the same side as the camera. With backlighting, the light is situated on the opposite side of the scene from where the camera is positioned. Next, there’s bright field and dark field illumination. Bright-field light is any light emission falling within the camera’s field of view boundary region (see figure 1c), while dark-field illumination originates outside of this boundary region.

Directed Vs. Diffuse Illumination

In directed light, each point on the scene is illuminated by a single ray of light or a group of rays spread at very narrow angles. Shadows cast by directed illumination are strong and accentuate texture. With diffuse illumination, every point on the scene is illuminated by a variety of rays coming from different directions. The shadows are faint or there are none, and there is no shading in the image that would indicate texture.

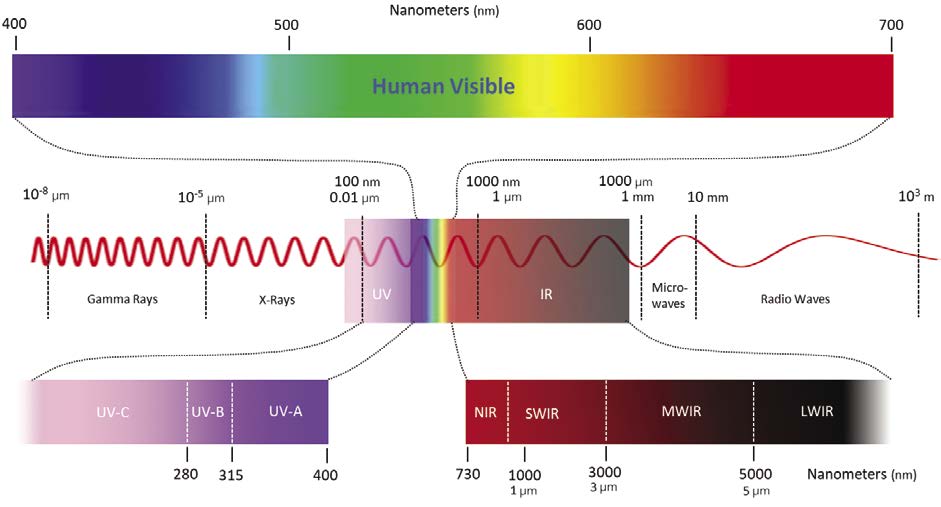

Another differentiator of engineered lighting is the spectrum of light used. While infrared wavelengths are being used in a growing number of applications, most machine vision systems operate at visible light wavelengths. Monochrome imaging typically uses a narrow range of red, green, or blue wavelengths while white light is necessary for color imaging.

Figure 2: Wavelengths delineate boundaries within the electromagnetic spectrum, showcasing the ultraviolet, visible, and infrared segments.

Knowing the rules and the tools that will lead to a solution is the first step in solving any challenge. Engineers designing machine vision systems put a lot of work into choosing and assembling the right LED illumination hardware based on geometry, structure, wavelength, and filters. It pays performance dividends to put as much effort into selecting the right LED lighting controller.

Machine Vision LED Lighting Driver Vs. Controller

The terms “driver” and “controller” are often used interchangeably in the context of machine vision LED lighting power and control. Typically, a driver is an internal device and a controller is an external one. However, it’s important to note that external/internal or embedded designs for both drivers and controllers exist and internal/external placement depends on specific device design and functionality.

Due to a lack of strict industry standards, term usage varies by industry and context. For this discussion, the key distinction between LED drivers and controllers is based on functionality and hardware presence rather than strict industry definitions. However, the industry marketing trend seems to categorize anything offering more than basic analog dimming or on/off capabilities as a controller, emphasizing the ability to adjust output based on user input, including features such s strobe capability.

In terms of functionality, drivers power LEDs efficiently and provide basic control like dimming. Features typically do not include a user interface, microcontroller, or computer. Drivers generally offer limited control options such as on/off and simple dimming but lack serial or smart communication interfaces. Drivers are often internal to the LED device, ensuring efficient LED operation with minimal user interaction. Conversely, controllers not only power LEDs but also offer advanced control via user interfaces. Controllers typically incorporate a driver within the overall architecture and may require more hardware and larger ports for connectors. Features generally include a user interface via serial communication interfaces such as USB or Ethernet. Flexible control options may include dimming profiles, color adjustments, and timing.

For this discussion, drivers prioritize efficient power delivery, offer mostly limited control such as on/off and dimming, and are often internal components within lighting systems. Controllers, on the other hand, enable more advanced functionality such as dimming curves, dynamic effects, communication protocols, and human interfaces for user interaction and advanced external control. Due to larger hardware requirements, they are usually external.

Choosing Between Current And Voltage Control Modes For LEDs

The driver most utilized is a constant current driver, which ensures that LEDs operate in constant current mode. While constant voltage mode drivers exist, the choice between voltage and current control mode affects the overall design, each having its own set of advantages and drawbacks.

LEDs generally perform optimally under constant current control due to the nonlinear relationship between voltage and current affecting LED brightness. Slight changes in voltage can cause substantial shifts in current, potentially damaging the LED if it’s not closely regulated. Various types of constant current drivers, such as buck mode and boost mode drivers, are available.

Buck mode drivers, used when the input voltage exceeds the LED string voltage, exhibit high efficiency, often surpassing 95%. They’re ideal for constant current, continuous mode lighting applications. Conversely, boost mode drivers, where the LED voltage exceeds the input, are slightly less efficient but find use in applications like strobe and overdrive, which require higher voltage to power larger or higher-current lights.

Voltage drive, often simpler to implement than current-driven solutions, involves manipulating voltage directly without the need for a dedicated driver. For instance, adding a resistor inside a light creates a voltage-driven setup but doesn’t quite meet the criteria for a proper driver.

Adding a resistor limits current to LEDs by creating an additional voltage drop, but it does not protect against over-voltage situations. To add protection, some LED controllers use voltage-based drivers, wherein an external box controller adjusts voltage levels to regulate the light.

But most machine vision LED lighting controllers rely on constant current drivers. In such devices, the controller modulates the current supplied to the LED while maintaining a more stable voltage output compared to voltage-based controllers. Controlling the current supplied to LEDs offers more precise management compared to voltage control.

The primary advantage of constant current over voltage drive lies in driving accuracy. Constant current control ensures more precise regulation of the LED’s performance, whereas voltage-based approaches might encounter greater variations in driving conditions. This distinction in driving methodology ultimately influences the overall effectiveness and accuracy of LED lighting systems in various applications.

Thermal Runaway In LEDs

In addition, the impact of temperature changes on LEDs can be considerable. For example, when an LED heats up, its forward voltage decreases. In scenarios where there’s a fixed voltage supply, the increased temperature causes the LED to draw higher current, leading to a phenomenon called thermal runaway. This state results in the LED drawing more power until it ultimately burns out, particularly affecting LEDs with poor thermal packaging when they’re used in voltage drive mode.

Conversely, employing current control mode maintains a fixed current, regardless of voltage fluctuations due to temperature changes. This approach ensures a steady, unchanging current flow, providing a high level of stability and preventing the LED from entering thermal runaway. Thus utilizing current control mode significantly reduces the risk of LED damage or burnout caused by temperature-induced voltage fluctuations. While these represent the primary variations, there are numerous other iterations and configurations available within the realm of LED drivers, each tailored to specific operational requirements.

To Control Or Not To Control

In terms of deployment expense and complexity, noncontroller machine vision lighting applications are the least costly and complex, but they are also the least flexible. Conversely, the more control options that a machine vision illumination system requires, the more expensive and complex the controller will be.

It is possible to choose from various types of current source controllers, ranging from simple units with limited features and lower power output to those with more features and higher power output. Controller performance and required control features drive costs. The following controller types can be found on the market today:

- Embedded LED Controllers: Also known as in-head or onboard controllers, embedded controllers are located inside the illuminator housing.

- External, or Discrete, LED Controllers: Fully disconnectable with tabletop or panel/DIN rail mounting, external controllers offer greater functionality and customization.

- Cable Inline LED Controllers: Permanently fixed in the cable (or provided with quick disconnects), inline controllers represent a cost-effective compromise, providing smart functionalities in a compact design adaptable for tight spaces.

Figure 3: a) The embedded controller is integrated within the light head; b) the inline controller aligns with the cable; and c) the external controller is a discrete unit.

Choosing the right LED lighting controller is crucial for optimizing the performance and accuracy of your machine vision system. The following sections explore the essential factors to consider when making this critical decision.

Embedded LED Controllers

Embedded controllers are entirely concealed within the metal body of the light, making them completely hidden from external view. In fact, users may not be aware of their presence unless they are explicitly mentioned in manuals or specification sheets. There is no doubt that embedded controllers are compact and can be easily installed, primarily because they require a simple cable, usually a four- or five-pin M12 connector,which can handle input power, triggers/gating, dimming, and/or strobe overdrives. As a result, performance, both in terms of available power and thermal dissipation, may suffer.

Thermal dissipation routes may be restricted due to the proximity of control electronics to LEDs. Additionally, high-power lights require more space for all the components, particularly strobe electronics, which typically rely on boost or buck drivers and capacitors, as well as other specialty elements, such as microprocessors. As a result, managing the strobe duration in many embedded LED controllers typically relies on simple on/ off signals, limiting the system’s ability to precisely control strobe parameters and push performance to its maximum potential. While embedded controllers can facilitate RGB control without an external controller, it’s more complex and challenging to achieve. Embedded controller light heads can also be more difficult to repair since they cannot be separated from the LED board easily, regardless of whether they are on daughter boards or mounted on the same circuit board.

On the plus side, embedded controllers are more easily expandable, in that they simplify cabling requirements when tiling, or assembling individual linear or array-based LED light modules into larger illumination systems. This ability to scale the system by adding more units incrementally allows for the creation of larger arrays or configurations in various formats, whether linear, backlit, square, rectangular, or another shape.

This scalability offers the advantage of user simplicity as the unit typically comes ready to use without requiring additional hardware. However, it’s important to keep in mind that many embedded systems may lack advanced user control features or software interfaces, limiting customization options for adjusting colors, sections, or quadrants, all of which are especially crucial in machine vision applications, where lighting geometry plays a significant role.

External LED Controllers

Since external controllers house components outside of the illuminator itself, they tend to be better suited to high-performance applications because they can integrate larger and more sophisticated components. When components are housed externally, there’s less concern about heat buildup within the light, allowing for increased control capabilities. This external setup also enables the possibility of fitting more functionalities into a package compared to an embedded controller.

External controllers can have their own thermal management systems and can be located remotely, which simplifies implementation in some cases. However, the cost and complexity may also increase. External controllers generally also allow for software interfaces, increased capacity for components such as larger capacitors or strobes, and the ability to save and load predefined recipes and achieve higher performance, along with improved precision and customization advantages.

Since external controllers allow for precise control over power and timing, they enable operations such as microsecond-level pulsing and programmable delays. They provide extensive illumination capabilities such as photometric stereo and advanced RGB color control that might not be achievable with other controllers. Additional inputs on external controllers allow for more precise adjustment settings for pulse widths, delay times, and specific duty cycles. By inputting these values, users can optimize strobe performance more effectively compared to embedded or inline control systems.

External controllers offer enhanced functionality and capabilities, such as greater control over strobe parameters, ultimately optimizing performance beyond the limitations of embedded systems. However, their downsides include higher costs, setup complexity, cabling, software, and additional space. Also, because they are confined to a single external box, external controllers can reach their power limits as the light array grows larger. This limitation poses challenges in scaling up the lighting setup beyond the capacity of the external controller.

While external configurations offer enhanced control capabilities, they typically come at the cost of convenience and increased expenses. Having a larger system external to the light means sacrificing some level of convenience and incurring higher costs due to the need for a separate, more extensive system.

Cable Inline LED Controllers

Essentially, cable inline controllers offer the best compromise between the cost and complexity of discrete controllers and the potential performance limitations of embedded devices. Inline controller systems are external, however, and are positioned close to the light, integrated along the cable. An inline controller may resemble an embedded controller that has been moved outside the light’s body due to size constraints and placed along the cable for practical reasons while maintaining proximity to the light source.

Inline controllers can include smart functionalities beyond a simple on/off or analog dimming and may include integrated circuit (IC) options, such as a potentiometer for adjusting brightness incrementally and ensuring uniformity across a light. Because inline controllers are located externally but still in proximity to the light itself, they offer some of the benefits of an external controller. However, unlike embedded controllers, they do not contribute to the thermal load within the light head. By eliminating the need for complicated PCB layouts for each light, inline controllers open the doors for lighthead miniaturization, leading to more compact and versatile illumination systems.

Since they are positioned along the cable near the light rather than being standalone units and are generally not detachable, inline drivers/controllers are still considered part of the light setup. Installing a system with an embedded controller can be easier than setting up a system with an inline controller because it only involves mounting the light and eliminates the need to mount an inline device or route wires separately. However, inline controllers tend to be smaller and significantly less expensive than embedded systems.

Inline drivers can cost-effectively cover around 80% of most users’ needs. With features such as smart trigger input, internal processing, and strobe and continuous dimming, as well as the ability to wire analog inputs, the inline controller fulfills the requirements of most machine vision lighting applications. However, inline controllers lack the flexibility, software interface, and power capabilities to drive larger lights, or even lights typically requiring more than 24 V to reach full potential in strobing operations.

Spatial Adaptability

In many instances, users customize the cable length between the light and the inline controller. This flexibility is particularly useful when mounting the light on a robot arm, enabling the placement of the driver at the base of the robot arm instead of at the end of the arm, which offers benefits in terms of robot or cobot payload. However, as the distance between the inline controller and the light increases, performance might diminish, especially in terms of power delivery over long lengths.

The maximum distance from the light that an inline controller can effectively function depends on the light’s size as well as the design of the driver output circuitry. Users commonly place the controller 2–5 meters from the light source, but for smaller lights, placement might extend beyond 5 meters. Once specified, the cable length between the light and the inline driver remains fixed. However, selecting an inline controller equipped with an M12 or M8 industrial connector gives users some flexibility in choosing the cable length on the power end, allowing easy modifications in the field.

The inline setup has three primary advantages. It’s cost-effective, user friendly, and versatile, allowing for the construction of lights in various shapes and sizes without restrictions. Despite being external to the light, inline controllers have a practical advantage due to their compact size. They can often be maneuvered through conduit and fitted into confined spaces. This spatial adaptability permits installation in tight areas, unlike discrete control systems or controllers requiring external boxes or cabinets that might not fit when space is limited. The inline controller’s drawback lies in power limitation — when the light reaches a certain size, the inline system cannot power it further.

In some cases, inline controllers can connect directly to certain camera systems for triggering signals and other inputs, depending on compatibility. For instance, lighting companies may offer an adapter cable for inline controllers with an M12 connector to link with specific camera models that may be equipped with a dedicated light output port. In such cases, the cameras can supply power to the lights, generally offering around 15–20 watts of power, sufficient for moderate lighting. While some cameras may support analog dimming, others may not.

Optimizing Illumination

Selecting the right LED lighting controller is a crucial step in optimizing machine vision system performance. To make the right choice, it’s critical to consider factors such as what level of control is needed for the specific machine vision task and whether a simple or complex lighting setup will be required. Budget constraints and space limitations are also important considerations.

Ultimately, the ideal LED lighting controller choice depends on individual project requirements. By balancing factors such as functionality, budget, and system complexity, machine vision engineers can leverage the power of light to achieve superior imaging and accurate results in their applications.

Key Takeaways

- Engineered lighting is crucial for reliable machine vision, and costs are a big factor as well, especially in complex machines, where some features may or may not be needed. Choosing the right LED lighting controller complements the hardware setup and optimizes image quality.

- Distinguish between drivers and controllers. Drivers provide basic power and dimming, while controllers offer advanced features such as user interfaces, communication protocols, and precise control over lighting effects like strobe and dimming profiles.

- Constant current control ensures LED stability and accuracy. This control method is preferred for machine vision applications rather than voltage-based control.

- External controllers offer greater functionality and customization. Their higher costs and setup complexity necessitate a tradeoff with convenience.

- Embedded controllers simplify cabling and scaling. However, they may lack advanced user control features and be bulkier due to integrated hardware.

- Inline controllers represent a cost-effective compromise. They provide smart functionalities while remaining compact and adaptable for tight spaces.

Interested in selecting a lighting controller for your machine vision application?

Click the link below to talk with our application experts.