Rochester, VT – We are proud to announce the release of our UltraSeal Washdown Backlights. The innovative BL245 UltraSeal Washdown Backlights are engineered with a sealed, flush surface, making them virtually crevice-free. The backlights are IP69K certified, ensuring they are protected against close-range high-pressure spray down while providing a dust-tight enclosure. The backlights are extremely resistant to corrosion and provide protection against common caustic solutions often used in food and beverage applications.

“We had quite a few customers approach us about an issue they had with other IP69K light offerings,” says John Thrailkill, Co-Founder and CEO of Advanced illumination. “Other washdown lights available on the market have cracks and crevices, which are created by the use of exposed screws and gasketing materials in the lights’ designs. This makes it more time consuming and difficult for the customers to clean the washdown lights, particularly for those in food and drug applications.”

The BL245 UltraSeal Washdown Backlights are built with a proprietary nickel finish and a flush-mounted, sealed diffuser. The proprietary nickel finish provides superior corrosion protection for the backlights while the aluminum housing makes them 11x more thermally conductive than stainless steel. The lights are available in multiple wavelengths and a variety of standard sizes, including: 4” x 4”, 4” x 8”, 6” x 6”, 8” x 8”, 8” x 12”, and 12” x 12”. The BL245 is half the thickness of other washdown backlights on the market, measuring 0.945”.

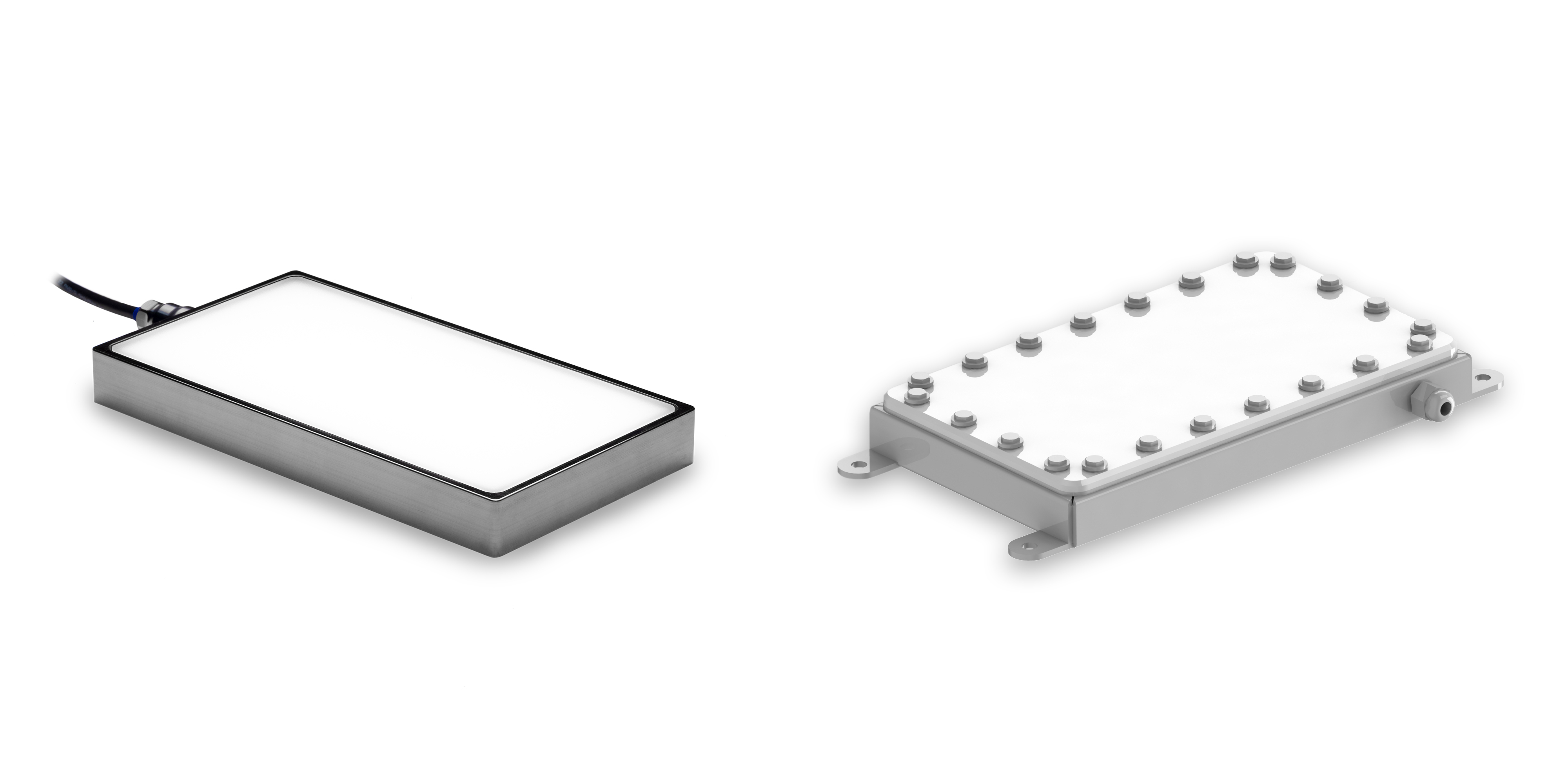

Ai UltraSeal Washdown Backlights vs. Competitive Washdown Backlights

Click for Larger Image

Due to their IP69K rating, the UltraSeal Washdown Backlights eliminate the need to have an additional enclosure, reducing costs when specifying machine vision applications. The washdown lights are ideal in applications that use corrosive washdown solutions and high-pressure steam cleaning operations. “Our main goal is to help our customers solve the issues they’re having; that’s what drives our innovation,” continues Thrailkill. “The UltraSeal family of products is our direct solution to the challenges they experience in these extreme environments.”

The BL245 Washdown Backlights are the first lights in the UltraSeal product line to be released. Our Engineering Team will continue to develop and release lights in the UltraSeal line intended to solve machine vision application challenges which rely on ultra-sealed, ultra-cleanable solutions. Our emphasis on quality processes and R&D ensures customers receive consistent, reliable machine vision lighting solutions; the Ai UltraSeal Washdown Backlights deliver on this promise.

Interested in getting more information on the Ai UltraSeal Washdown Lights? Click the button to contact our Sales Team!