Quality.

It’s a claim many companies make when describing their products. “High-quality components”, “lasting product quality”, “quality customer service” – the list can go on and on. At Advanced illumination, we also claim to deliver quality LED lighting solutions to our customers… only we can prove it.

Through our stringent product testing of every light that leaves our facility, our streamlined production documentation system, and the ISO 9001 process that facilitates continuous improvement – we deliver the highest quality, most reliable lighting solutions for your machine vision application.

Ai Quality – Consistent Product Testing

To gauge the performance and reliability of our lights, we pass every single light through the Ai Quality Department for individual inspection. This is an uncommon practice that’s special to Ai Quality; rather than a sample testing process on which many other manufacturers rely, each Ai product is hands-on inspected prior to being shipped. You read that correctly: every single product that comes from the production floor is physically inspected and tested by our Quality Team to ensure each product will perform as anticipated.

This hands-on approach to quality testing is imperative in providing reliable LED lighting, as it provides individual attention to customer orders. But how does the Quality Team find the time to test every single light?

Customer-Specific Testing Parameters

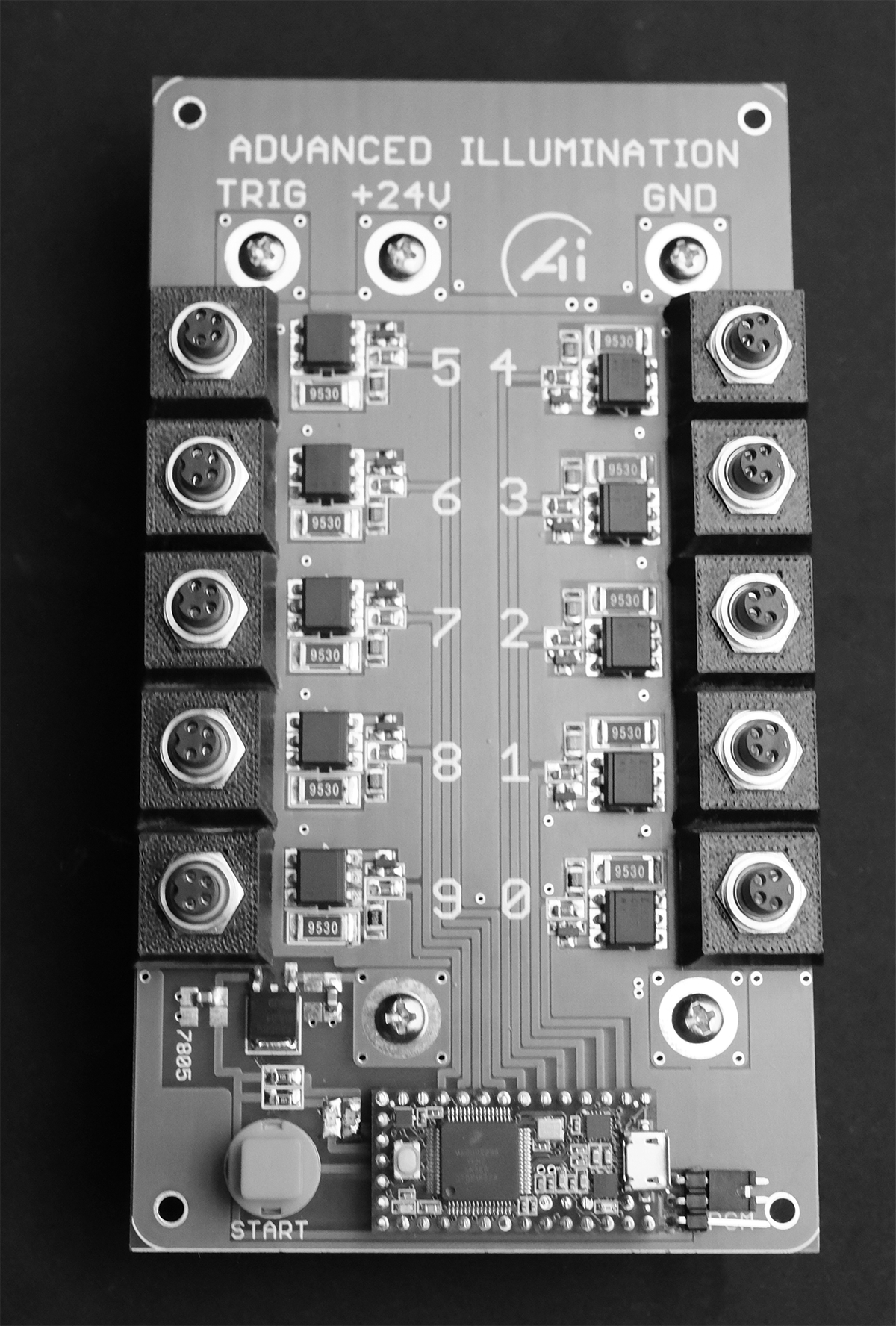

To test these products to the highest considerations, our Quality Team engineered “burn-in stations” to facilitate accelerated stress testing for our controller-based products. Each light with an in-line controller is stress-tested to ensure the safety precautions built-in are assessed to have significantly lower risk of failure in the field.

Should a customer have unique parameters for a custom light, the Ai Quality Team has built specially designed plates that can be swapped in and out of the burn-in stations to test lights at various specifications, including strobe rate. This is all to ensure the lights will work properly in each customer’s environment – making the stringent testing of quality an absolute necessity.

Additional Testing Benefits: Consistent LED Intensity

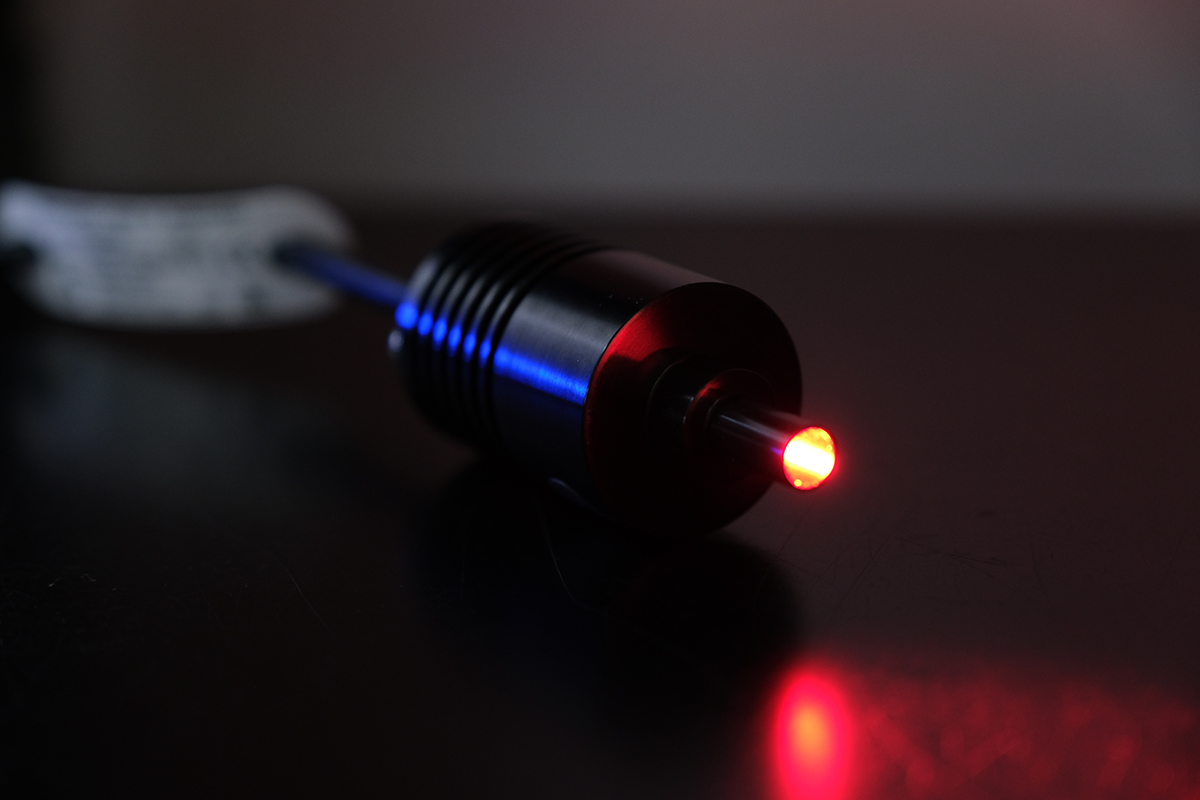

In addition to testing for potential failures, there is an additional benefit to stress testing. When first powered up, LEDs have an initial higher intensity period before plateauing for the middle 80% of their useful lifetimes. Deploying a light before this initial high-output period is over could require some users to make initial adjustments in more sensitive machine vision systems that may later need to be reversed. By performing pre-shipment burn-in on every light, Ai ensures our customers receive lights that perform more consistently for the remainder of their lifetimes.

Since the Quality Team works closely with our customers, they understand what our customers have experienced in the past – the good, the bad, and everything in between – and they use that information to develop the high-stress testing environment for each and every product that leaves our facility.

Building a Better, More Consistent Light

The process of testing a light is significantly more efficient when the lights themselves are precisely-built from the beginning. At Ai, we utilize a Digital Documentation system to address this need. With this system, the Ai Production Team has the benefit of working from a digital document containing all of the detailed information pertinent to the product being built.

Even with the wide variety of products we offer, our Production Team continues to hand-place LEDs within some of our lighting solutions, particularly in our custom-built lights, to ensure precise aiming and exact spec build. Some lights may have electrical and mechanical information, while others feature supporting documentation such as compliance information and identification location information.

Thanks to the Digital Documentation system, each member of our Production Team is armed with every necessary detail to build custom, intricate LED lighting solutions – translating to quality lights from the very beginning.

Continuously Improving for High-Quality Results

Clearly, the Ai Production and Quality Teams are focused on customer satisfaction and the tiniest details of our lighting solutions. But what may be the most important component: they’re not done working to improve them.

Ai is ISO 9001 Certified, meaning we are continuously addressing the standardized processes and quality assurance within our organization – and we never stop searching for improvements. According to Bill Brochu, our Quality Manager, “it’s both internal and external for us. Anything that we see happen, we look at the root cause of it, and adjust our processes in ISO to make sure it doesn’t happen again. Our ISO system gives us the baseline of how we do business – directly influencing how our processes affect our products, and ultimately our customers.”

Ai’s Ultimate Trinity: Testing, Documentation, Improvement

When you step back and combine all three factors – intense product testing, meticulous building documentation, and a frequent focus on process improvement – it all translates to a genuine claim of “product quality”. Or again, as Bill Brochu says, “it is all about continual improvement; constantly looking introspectively to make sure our roadmap is driving our everyday business to ensure we’re meeting our customers’ needs.”