PHOTOMETRIC STEREO

Table of Contents

Introduction to Photometric Stereo

Application Examples Using Photometric Stereo

Ai Products Compatible with Photometric Stereo

Supporting Technical Documentation

Introduction to Photometric Stereo

Machine vision is commonly deployed in part inspections to gather feature-appropriate identifying information from an object’s surface and to increase the speed, accuracy, and consistency of the inspection process. For many surfaces, simple defects such as scratches and dents are easily identifiable with a machine vision camera and a traditional lighting solution.

However, some objects have 3D aspects that make accurately identifying surface defects more difficult, such as embossing, textured or highly reflective surfaces, as well as those objects exhibiting little to no feature contrast or texture. A standard vision light and camera configuration, typically used in machine vision, only captures images from a single illumination/viewer perspective. Therefore, it may be ineffective in certain applications, because local surface shapes (including embossing or other 3D details) cannot, in general, be determined from the intensity value recorded at a single image point. To achieve feature-appropriate surface contrast on these difficult object surfaces and ultimately gather a 3D perspective, Photometric Stereo may be applied to vary the direction of incident illumination between successive views, while holding the viewing direction constant.

Achieving Surface Contrast with Photometric Stereo

Photometric Stereo is an application of the surface albedo, or the fraction of the incident light that a surface reflects, to produce an image with enhanced contrast and diminished surface noise. An important factor in Photometric Stereo for machine vision is that the surface albedo is a direct result of the spectral and angular distributions of the incident light rather than any inherent characteristic of the object being inspected – meaning an adjustment of the illumination on the surface of the object will result in an identifiable, adjusted surface albedo. In effect, Photometric Stereo techniques separate the surface albedo from the underlying surface shape by exploiting surface reflectivity variations as a function of changes in incident illumination direction, with respect to a static viewer orientation.

Photometric Stereo then relies on a change in the direction of illumination, a static camera, and software to process the resulting multiple images. An image is typically acquired from each of four quadrants, effectively producing a series of automatically registered images, each from a different light source direction. To process the images, the Photometric Software tracks specific points on the object throughout each of the captured images, owing to the variation in surface reflectivity generated from the different point source directions, with respect to the static camera point of view. It then processes the images together to establish local surface properties and recreate the local shape of the object, producing an image with acceptable contrast otherwise unidentifiable with a single light/camera inspection setup.

Components of Photometric Stereo in Machine Vision

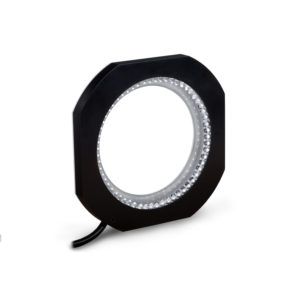

To achieve the multiple incident angles of illumination, one may use either a multi-segmented light, such as the DF198 MicroBriteTM Diffuse Ring Light or a multi-light station driven by a multi-channel lighting controller. Each option provides the opportunity to illuminate from multiple source directions, or with multiple wavelengths, to achieve the necessary differing surface albedos.

Application Examples Using Photometric Stereo

Sample inspections applying Photometric Stereo benefit from the ability to “flatten” surfaces with 3D characteristics that can distort an image in common machine vision applications. The following sample applications feature varying challenges to demonstrate the benefits of applying photometric stereo.

Sample Application:

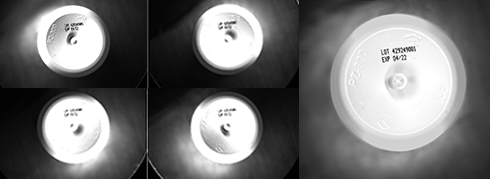

Bottle Printed Lot Code Inspection

In this example, we are inspecting a printed lot code on the bottom of a glossy vitamin bottle. Because of the reflective and concave surface characteristics of the bottom of the bottle, it is difficult to illuminate the printed lot code without excessive specular reflections.

Sample Application:

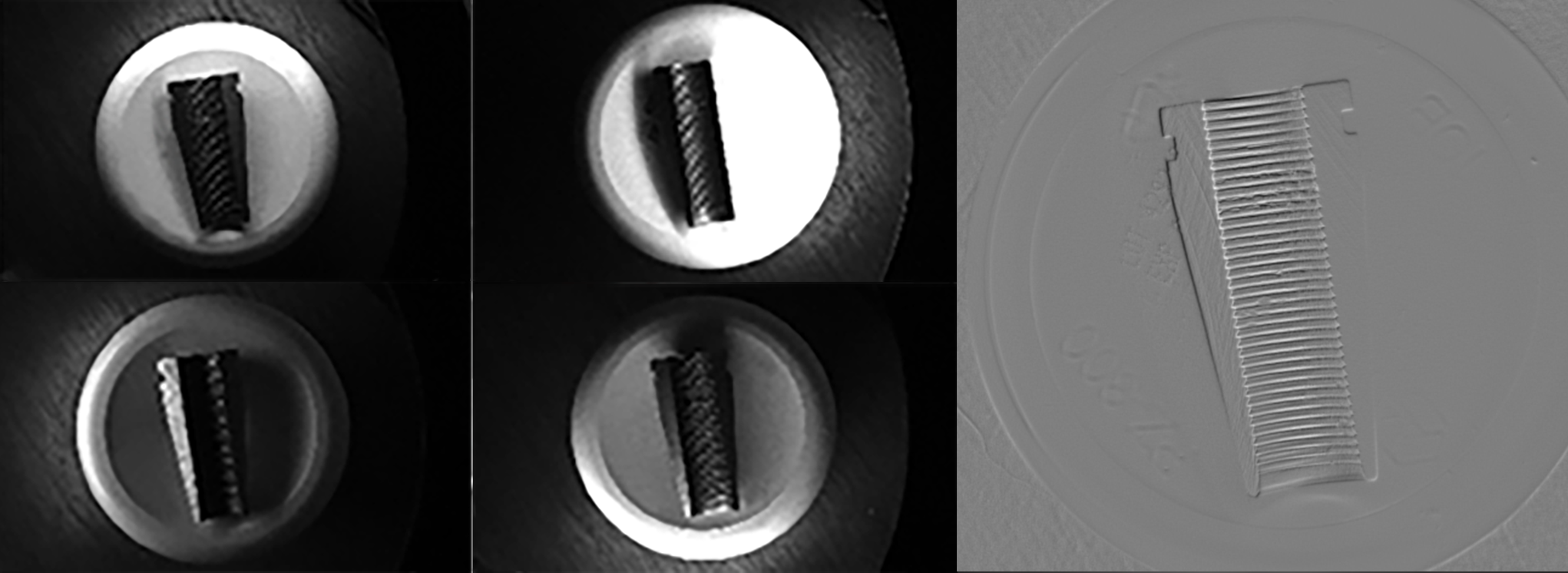

Threaded Metallic Part

The inspection of a threaded metallic part presents a challenge for standard vision light and camera configurations. The varying heights of the object’s threads create significant shadowing, making it very difficult to visually inspect for defects. The metallic surface also presents a challenge with unwanted glare.

Ai Products Compatible with Photometric Stereo

Lights and Controllers Configurable for Photometric Stereo

For applications that require multi-channel lights, such as Photometric Stereo and/or multi-light stations, our Quad Controllers are the ideal lighting controllers. Multi-light stations are currently limited to a group of identical light heads, wired with the same cable lengths into a common Quad (Q4) Connector. Varying cable lengths can be made available, please consult the factory. A future development will allow the Quad Controllers to drive up to eight different configured lights simultaneously.

Below are the current Ai products compatible with Photometric Stereo. As a note, due to power output constraints, some configurable light lengths may be limited.

DCS-400E Quad Controller

The DCS-400E provides a total of 4 channels, each capable of firing independently. Built-in, pre-programmed sequencing allows users to progress through pre-determined recipes. This provides users the ability to automatically time a lighting sequence and output a correlated camera trigger, and to do so through multiple pre-programmed routines. Ideal for computational imaging applications, including photometric stereo, extended depth of field, combined bright field + dark field, high dynamic range, and high resolution color.

DCS-800E Quad X2

The DCS-800E provides a total of 8 channels using 2 outputs, each channel capable of firing independently. As with the DCS-400E, it provides control for computational imaging, including photometric stereo, extended depth of field, combined bright field + dark field, high dynamic range, and high resolution color. The Quad X2 also uses the same connector as the Quad Controller to run lights in a Photometric Stereo configuration.

DF198 MicroBrite™ Diffuse Ring Light Series

Our MicroBrite™ DF198 Diffuse Ring Light Series is a series of multi-segmented lights, each featuring four separate quadrants. Each quadrant provides the opportunity to illuminate from multiple directions or with multiple wavelengths. It also provides diffuse illumination at a low angle to cast shadows used to identify surface defects, embossed text, etc. Can be used to produce a bright field effect when the outer diameter is smaller than the working distance. Available in four sizes, with inner diameters ranging from 50mm (1.97″), 113.3mm (4.46″), 180mm (7.09″), and 280mm (11.02″).

DF241 Small Low Angle Dark Field Ring Light

With a light intensity of 24klx at a working distance of 1″ (12.5mm), the DF241 is ideal for imaging problems limited to a small field of view. Precisely aimed LEDs provide a very low angle of incidence with a radial illumination pattern.

DF242 Large Low Angle Dark Field Ring Light

With a light intensity of 24klx at a working distance of 1″ (25mm), the DF242 is ideal for imaging problems with medium size fields of view. Precisely aimed LEDs provide a very low angle of incidence with a radial illumination pattern.

LL174 High Intensity Bar Light

The LL174 Series of High Intensity Bar Lights feature a degree of available customization, including sixteen wavelengths, optional heat sink for higher performance, optional light conditioning including polarization and diffusion, and three lens options for narrow, medium, and wide beam spreads. The Bar Lights are expandable in 6″ (150mm) increments up to 84″ (2.13m).

AL295 MicroBrite™ Bar Light

The AL295 MicroBrite™ Bar Lights deliver high performance in a compact form factor. These Bar Lights are available in a broad range of wavelengths with expandable sizes in 3″ (75mm) increments up to 18″ (450mm).

AL116 High Dispersion Wide Bar Light

The AL116 is a high dispersion Bar Light that provides both a wide and intense illumination area. The compact AL116 is highly customizable, engineered with expandability and available with optional washdown features. The AL116 is also available with polarization and diffuse light conditioning, as well as with a wide spectrum of wavelengths.

AL126 High Dispersion Narrow Bar Light

The AL126 is a high dispersion and expandable compact bar light, providing a narrower and less intense illumination area than the AL116. The AL126 is customizable with an IP65 washdown option, a variety of available wavelengths, and polarization and diffusion light conditioning options.

LL232 MicroBrite™ Line Light

High performance and compact, the LL232 MicroBrite™ Line Light utilizes a Fresnel lens for a compact form factor. The LL232 provides an intensity level of 189klx at a working distance of 3″ (75mm), and is expandable in 50mm (2″) increments up to 750mm (29.5″).

SL243 MicroBrite™ Small Spot Light

The SL243 MicroBrite™ Spot Light provides an industry-leading performance to size ratio, while maintaining desirable thermal dissipation. Perfect for applications that require small footprint machine vision components, and highly customizable with a range of wavelengths and an optional washdown version available.

SL244 MicroBrite™ Spot Light

Much like the SL243, the SL244 MicroBrite™ Spot Light features high-intensity illumination in a compact package. Customizable with sixteen wavelengths and an available washdown option.

Supporting Technical Documentation

The following documents offer detailed technical information for the incorporation of the Ai Quad Controllers into Photometric Stereo applications.

DCS-400E & DCS-800E User Guide

DCS-400E & DCS-800E Quad Controller Manual

DCS-400E Quad Controller Spec Sheet

DCS-800E Quad X2 Spec Sheet

Ultimately, Photometric Stereo is a method for producing robust inspection images from challenging topologies, including highly reflective objects or surfaces with problematic 3D characteristics. While there do exist techniques that utilize creative illumination geometries to achieve adequate results, even these techniques can fall short, prompting the need for more involved lighting solutions.

Under these circumstances, a quadrant light or multi-light setup, with a multi-channel lighting controller, and dedicated processing software libraries deliver a Photometric Stereo solution ideal for challenging inspection applications. For detailed information on Ai lighting products available for Photometric Stereo, contact our team today!